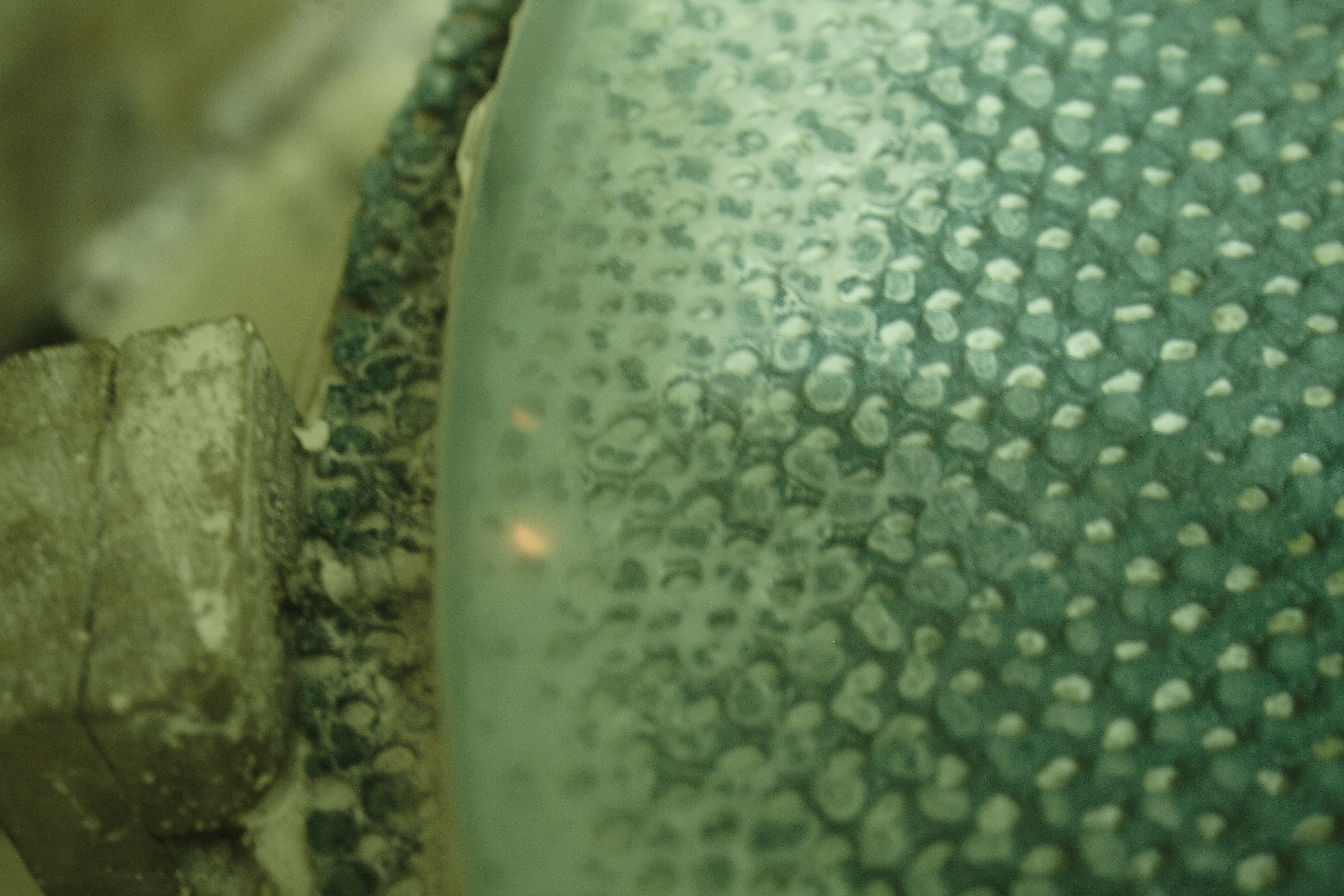

I remember the amount of labor that went into the previous mirror I had made as I sit and watch the rotation of this new mirror on my rudimentary machine spinning and spinning. I spent a total of six years on the previous one, about 3 of those were trying to figure out the “figure”. This is hands down the most difficult task at mastering mirror making, and I am in no way claiming I have done that. All those years spent was learning and perfecting, and trying to create a high quality piece of glass. Unfortunately, that mirror had turned down edge, something I tried to correct for probably 1.5 of those 3 years. But I am not at that stage yet for this new mirror, and my challenge still is to get the spherical mirror completely polished out. I’ve spent a total machine polishing time of 10 hours (approximately) and things are going quite well, knock on wood. This is the time where a silly or stupid error can screw up the process. To prevent this, one needs to constantly be thinking about that errant spec of dirt or sand or other hard substance that can somehow find its way on to the mirror surface before you begin polishing. One must always think in terms of what can fall on the mirror before you begin each session. Washing the lap every time you start a new polishing session in absolutely essential. The closer you get to competing the polishing stage, the more important this is. It would be very painful to start over. Now, there can be somewhat of an exception to this. By using a machine that I have designed and built my self, I have calculated my reduction in the time to manufacture this mirror from 6 years to 6 months. This is 1200% less time I would have spent not having the machine! So if a minor error would occur, like a scratch from a particle, at least I can rely on a mechanical means to expedite the process. The good news, is I am not in that predicament. So let’s discuss the situation I am in. As I said, after 10 hours of machine polishing, I would have expected, and hoped I would have been completely polished out at this time. But I am not. To determine if you are, it is essential to have a small laser available as I have previously mentioned on this site. Looking at the image below,  while being somewhat difficult to see, is a small red laser that is shined directly on the mirror surface. If it passes through the top surface of the mirror (polished surface is facing up) then the polishing can considered to be complete. In this image the green tone is caused by the color of the glass. In this case I am using plate glass for the mirror, and also by the green non-skid table place mat I am using to support this mirror when I am polishing. Now as I a have mentioned, I am still not completely polished out, and this is near the edge of the mirror. The previous image was near the center of the mirror, which would be expected if everything is going as planned. The image below, is where the laser is now visible on the top surface of the mirror and partially on the bottom support mat. This is an indication of more polishing needed.

while being somewhat difficult to see, is a small red laser that is shined directly on the mirror surface. If it passes through the top surface of the mirror (polished surface is facing up) then the polishing can considered to be complete. In this image the green tone is caused by the color of the glass. In this case I am using plate glass for the mirror, and also by the green non-skid table place mat I am using to support this mirror when I am polishing. Now as I a have mentioned, I am still not completely polished out, and this is near the edge of the mirror. The previous image was near the center of the mirror, which would be expected if everything is going as planned. The image below, is where the laser is now visible on the top surface of the mirror and partially on the bottom support mat. This is an indication of more polishing needed.  Of significance here, is the fact that it is near the edge of the mirror. The edge of the mirror has more influence on the image than the center of the mirror. Generally,this is the case from the edge to the center, therefore it is more important to have an excellent edge polished out than the very center of the mirror. This, not only from an optical standpoint, but is also because the center of the mirror, approximately 20%, is actually blocked by the secondary mirror in the secondary mirror cage, and no incoming light reflects from that area. In fact, if it were feasible to not even polish it, the telescope would still perform perfectly, because there is no light that can be received by the area behind the secondary shadow anyway. So, at this point, and to summarize, I must continue to polish, and completely remove any evidence of grayness or haziness on the mirror edge. Continue to test with the laser, and when this is not evident. I can move on to figuring, well, maybe. but the step before that is to put the mirror on the test stand. This a completely new stage of the making of the mirror, and exciting time, though because now you are working with an actual reflecting surface, which is beautiful, and gratifying. Soon, soon, but need to complete polishing!!! Stay tuned!

Of significance here, is the fact that it is near the edge of the mirror. The edge of the mirror has more influence on the image than the center of the mirror. Generally,this is the case from the edge to the center, therefore it is more important to have an excellent edge polished out than the very center of the mirror. This, not only from an optical standpoint, but is also because the center of the mirror, approximately 20%, is actually blocked by the secondary mirror in the secondary mirror cage, and no incoming light reflects from that area. In fact, if it were feasible to not even polish it, the telescope would still perform perfectly, because there is no light that can be received by the area behind the secondary shadow anyway. So, at this point, and to summarize, I must continue to polish, and completely remove any evidence of grayness or haziness on the mirror edge. Continue to test with the laser, and when this is not evident. I can move on to figuring, well, maybe. but the step before that is to put the mirror on the test stand. This a completely new stage of the making of the mirror, and exciting time, though because now you are working with an actual reflecting surface, which is beautiful, and gratifying. Soon, soon, but need to complete polishing!!! Stay tuned!

Polishing Update

Leave a reply